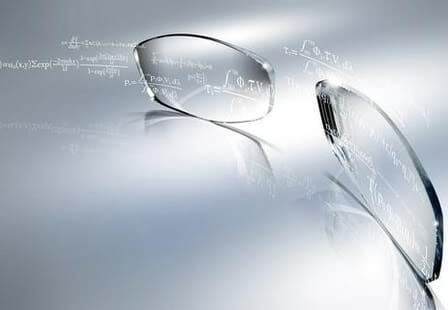

New Lenses Leverage Free Form Technology

This is big. Maybe you’ve heard your optometrist talking about digital surfacing. Or maybe there’s been a little bit of buzz around the phrase “free-form surfacing.” So what exactly is it, and why is it such a big deal?

The most progressive surfacing technology is now impacting the world of lenses. Through the use of a three-axis CNC generator (that stands for “computer numerically controlled”), any single point tool typically used for cutting a lens can now be manipulated to produce just about any surface shape possible.

According to an article in 20/20 Magazine, this includes “complex surface shapes” like “aspheric, atoric and even progressive addition surfaces.” And because the shape is generated through the use of a computer, there will always be an amazingly “high degree of accuracy and smoothness.” And once the lens has been cut, the polishing can also be handled dynamically by the computer.

Now, it is possible for a lab to take a semi-finished lens blank, and then apply this technology to directly surface the lens (in addition to the required curves of the prescription).

According to the same article, “With two surfaces to work with, free-form progressive lenses represent a combination of factory-molded and free-form-surfaced lens curves that range in complexity from simple spherical surfaces to progressive surfaces that have been combined with the prescription curves.”

To learn more about progressive free form technology, you can read the full article here at 20/20 Magazine.

And here is another great piece of writing on free form lens technology, at Midwest Lens blog.

[Photo Via: midwestlens]